Although the power of a vacuum was first witnessed over 350 years ago, vacuum chuck technology is often overlooked in the manufacturing community. In this tutorial we’ll cover some basic limitations and to see if vacuum chuck workholding is right for your application.

To Vac or Not to Vac

In a machining environment a vise should always be the first choice in workholding due to the high mechanical clamping force. However, using a vise is not always an option for certain materials and shapes. Some soft or thin materials can be damaged or bowed by a vise. Using a vacuum chuck also allows machining of 5 out of 6 full sides of a part – vises allow limited exposure of 3 sides. If using a vise causes any of these problems, then a vacuum chuck is absolutely an ideal workholding device. The rule of thumb in evaluating if vacuum chuck workholding is right for you is best remembered by the phrase “Short and Fat”.

Evaluating the Workpiece

“Short and Fat” conveys two ideas. First, parts are best held when a large surface area (fat) is presented to the chuck surface. A high vacuum is defined as 26″ – 30″ Hg and produces a holding force of 13 – 15 PSI. For example, a 5″ x 5″ part being held by a vacuum chuck at 28″ Hg (or 14 PSI) has 350 lbs of downward holding force applied to it (5″ x 5″ = 25 sq in. 25 sq in x 14 PSI = 350 PSI). The more surface area a part has, the stronger the hold, the more aggressively material can be removed.

Vises have a theoretically infinite amount of pressure that can be applied to a workpiece whereas vacuum chucks rely on the atmospheric air pressure around us to press a workpiece downward against the chuck surface. Since this force has a limit of 14 pounds per square inch (14 PSI), any forces that might lift the part should be avoided. Rather, material removal should be focused on creating sideways forces, but sideways forces on tall parts can lead to unwanted lifting due to leverage. Short parts do not experience this unwanted leverage.

Vises have a theoretically infinite amount of pressure that can be applied to a workpiece whereas vacuum chucks rely on the atmospheric air pressure around us to press a workpiece downward against the chuck surface. Since this force has a limit of 14 pounds per square inch (14 PSI), any forces that might lift the part should be avoided. Rather, material removal should be focused on creating sideways forces, but sideways forces on tall parts can lead to unwanted lifting due to leverage. Short parts do not experience this unwanted leverage.

How tall is too tall? Plugging in a 25:1 ratio into a simple equation offers a good starting point. Divide a part’s surface area by 25 to find a safe part thickness (5″ x 5″ = 25 sq in. 25 sq in / 25 = 1″ tall part). Many other factors play into this equation such as material type, cutter style, feed rate, aggressiveness of cut, etc. so fine tuning to the exact application is encouraged.

“Short and Fat” reminds us of the ideal part shape, but trying to keep a part in place while cutting on it is a discussion for another tutorial.

Vises have a theoretically infinite amount of pressure that can be applied to a workpiece whereas vacuum chucks rely on the atmospheric air pressure around us to press a workpiece downward against the chuck surface. Since this force has a limit of 14 pounds per square inch (14 PSI), any forces that might lift the part should be avoided. Rather, material removal should be focused on creating sideways forces, but sideways forces on tall parts can lead to unwanted lifting due to leverage. Short parts do not experience this unwanted leverage.

Vises have a theoretically infinite amount of pressure that can be applied to a workpiece whereas vacuum chucks rely on the atmospheric air pressure around us to press a workpiece downward against the chuck surface. Since this force has a limit of 14 pounds per square inch (14 PSI), any forces that might lift the part should be avoided. Rather, material removal should be focused on creating sideways forces, but sideways forces on tall parts can lead to unwanted lifting due to leverage. Short parts do not experience this unwanted leverage. Atmospheric air pressure exists around 30″ Hg or 15 PSI at sea level (Yes, every square inch of our bodies has 15 lbs of air constantly pressing on us). This is why passengers on planes flying at high altitudes can experience swelling due to lower pressures in the cabin. Cabins are typically pressurized to an equivalent of being at 8,000 ft above sea level. At this altitude there is roughly 11 PSI of air pressure. Translate this into workholding and users at higher altitudes will experience a significant drop in holding force equating to a loss of 0.5 PSI per 1,000 ft above sea level. A high powered vacuum pump operating in outer space would be completely ineffective.

Atmospheric air pressure exists around 30″ Hg or 15 PSI at sea level (Yes, every square inch of our bodies has 15 lbs of air constantly pressing on us). This is why passengers on planes flying at high altitudes can experience swelling due to lower pressures in the cabin. Cabins are typically pressurized to an equivalent of being at 8,000 ft above sea level. At this altitude there is roughly 11 PSI of air pressure. Translate this into workholding and users at higher altitudes will experience a significant drop in holding force equating to a loss of 0.5 PSI per 1,000 ft above sea level. A high powered vacuum pump operating in outer space would be completely ineffective. The atmosphere likes to remain at a constant level and it is this principle that causes the wind to blow – air flows from high pressure to low pressure. When objects are tossed around by the wind, they are acting as obstacles to this high-pressure-to-low-pressure flow. When a vacuum chuck is turned on the air pressure decreases below the workpiece which causes higher air pressure above the workpiece to want to fill this low pressure space below it. The workpiece becomes an obstacle which is pressed against the chuck.

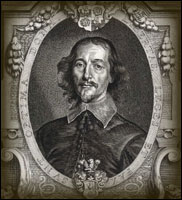

The atmosphere likes to remain at a constant level and it is this principle that causes the wind to blow – air flows from high pressure to low pressure. When objects are tossed around by the wind, they are acting as obstacles to this high-pressure-to-low-pressure flow. When a vacuum chuck is turned on the air pressure decreases below the workpiece which causes higher air pressure above the workpiece to want to fill this low pressure space below it. The workpiece becomes an obstacle which is pressed against the chuck. In 1650, Otto invented a vacuum pump that was designed to pull air out of whatever vessel to which it was connected. It contained a piston and an air-gun cylinder with one-way flap valves. In many subsequent experiments, he used it to study the effects of vacuum. The most famous involves two copper hemispheres, closed tightly with the air pumped out of them. On May 8, 1654, in front of the Holy Roman Emperor, Guericke harnessed fifteen horses to each hemisphere and showed that they could not be pulled apart. In 1663, he repeated this experiment in front of the Duke of Prussia with twelve horses to each half. If the air were completely sucked out of the sphere, the resulting force would be around 4,500 lbs, enough to lift a small car. The surrounding air pressure would have shut the halves tightly and prevented them from being opened.

In 1650, Otto invented a vacuum pump that was designed to pull air out of whatever vessel to which it was connected. It contained a piston and an air-gun cylinder with one-way flap valves. In many subsequent experiments, he used it to study the effects of vacuum. The most famous involves two copper hemispheres, closed tightly with the air pumped out of them. On May 8, 1654, in front of the Holy Roman Emperor, Guericke harnessed fifteen horses to each hemisphere and showed that they could not be pulled apart. In 1663, he repeated this experiment in front of the Duke of Prussia with twelve horses to each half. If the air were completely sucked out of the sphere, the resulting force would be around 4,500 lbs, enough to lift a small car. The surrounding air pressure would have shut the halves tightly and prevented them from being opened.